This suggests that the doable microbial contamination of the procedure and/or merchandise really should be prevented in advance of it happens. Consequently, the standard units of manufacturing and/or producing units need to make sure aseptic procedure, good sterilization techniques, sterility assurance, quality Command and assurance; as well as the microbiological and Bodily parameters of your generation procedure need to be constantly monitored through output to attenuate contamination with the finished biological products.

Membrane filtration entails passing a regarded volume on the sample via a sterile membrane filter. The filter retains any microorganisms present inside the sample when letting the sterile liquid to go through.

Drug Material — Tested mostly for characterization reasons to show product and process purity profile

This document discusses sterility testing protocols for pharmaceutical products According to Indian Pharmacopeia guidelines. It defines sterility testing as testing to substantiate absence of feasible microorganisms. Sterility testing is very important for professional medical products and preparations like ophthalmic, injections, implants and so forth.

A simple and brief presentation over the phenol coefficient having a movie explanation of the exam procedure.

Ought to get an item examined? No worries! To and fro logistics are on us; we collect your products, exam them and, supply them back to you personally.

Each individual sublot need to be tested as being a separate sterility examination. The amount of vials for your sterility check is dependent on the quantity of every pharmaceutical vial and is also outlined in USP seventy one.

Lowering h2o in dry generation environments for very low moisture foods is vital to managing environmental contamination. Keep an eye on Enterobacteriaceae (EB) populations on surfaces in dry creation regions — existence of EB can be an indicator that unpredicted drinking water may have been released.

This doc discusses in-system good quality Handle (IPQC) assessments for parenteral products. It describes numerous key IPQC checks like drug content material assays, clarity testing to detect particulate make a difference applying various methods, leakage testing of ampoules utilizing dye tub or spark tests, sterility testing using membrane filtration or direct inoculation methods, and endotoxin/pyrogen testing.

Completely ready-to-use High-quality Command Designs aid the entire choice of biosafety testing at just about every action, shortening time it requires to obtain results.

If progress is discovered, supplemental exams are executed to recognize the contaminant, as well as testing problems are reviewed to rule out faults.

The USP seventy one sterility testing conventional is relevant to an array of products, like but not website restricted to:

This technique is useful for companies with a significant product portfolio, mainly because it avoids the necessity for different validation of each and every product, preserving time and resources.

Also, as stated, each terminal sterilized sublot of an item batch need to be examined separately based on the regulatory specifications outlined in USP seventy one. The volume of vials examined is set by the dimensions of every sublot.

Alana "Honey Boo Boo" Thompson Then & Now!

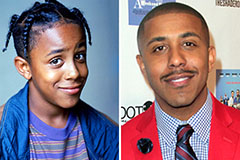

Alana "Honey Boo Boo" Thompson Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!